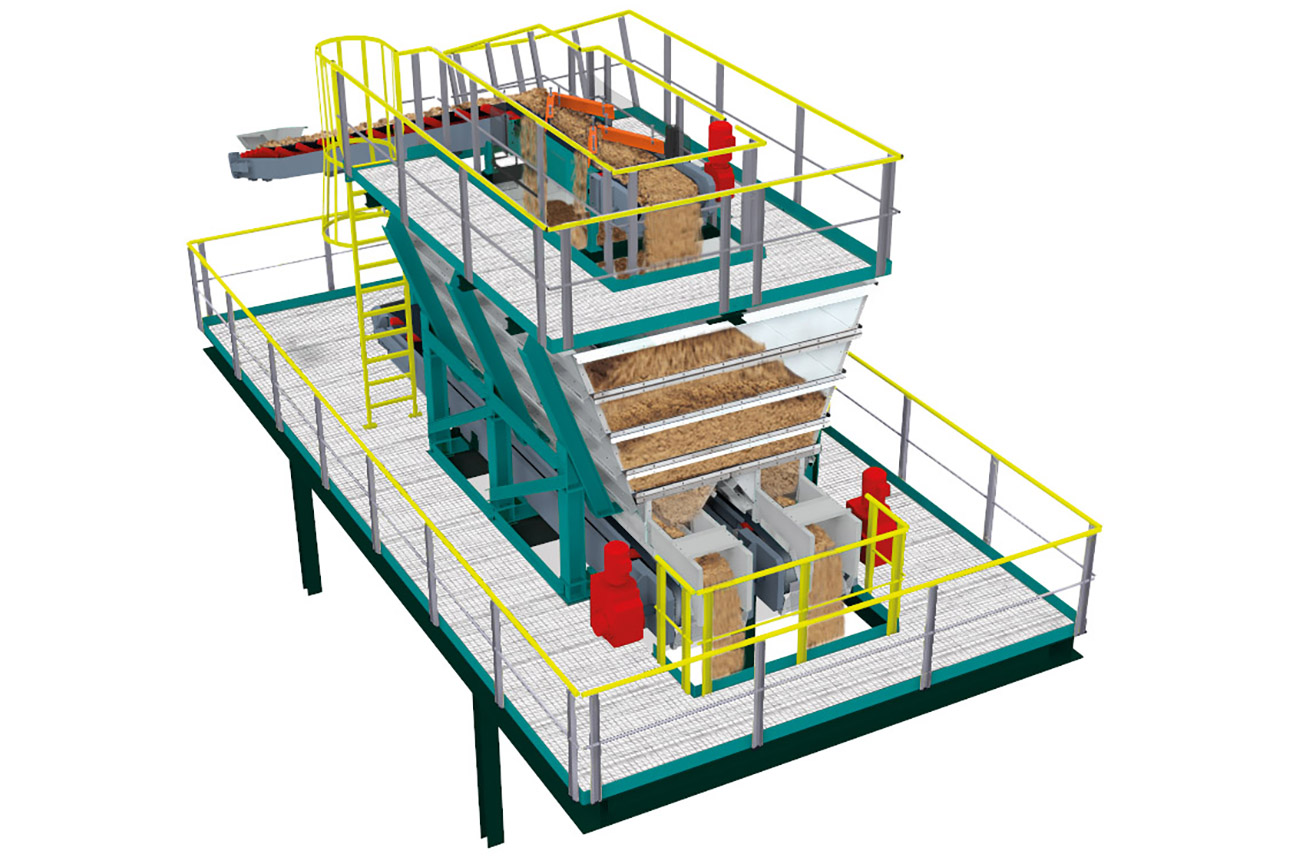

VHV dosing and weighing systems

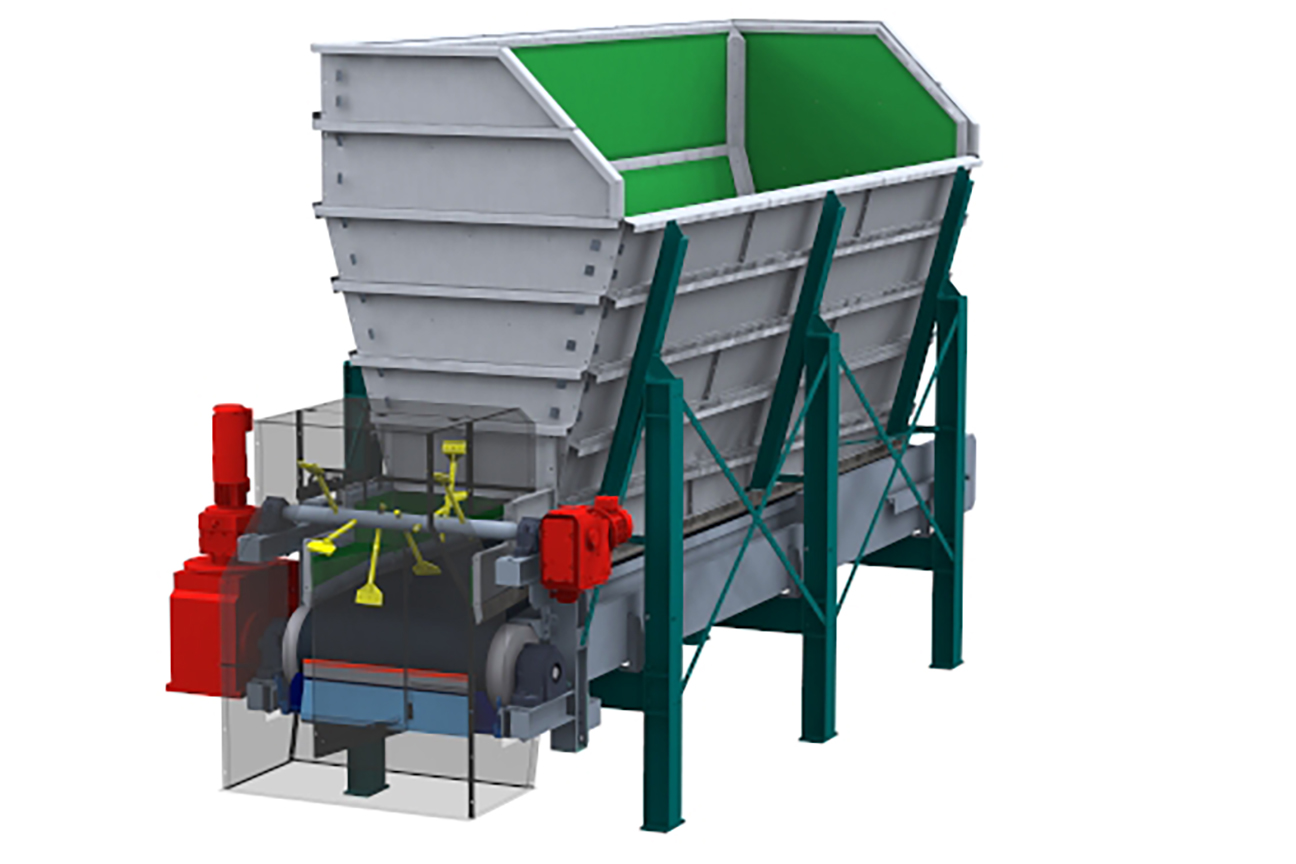

Box feeders:

A bunker system featuring per-segment screwed sections avoids expensive welded designs

Bunker dimensions, lateral inclinations and discharge forces are designed to match your product

Conveyor performance can be adjusted with speed controls and layer heights

Practical choice of drive sizes

We can also supply additional equipment such as coiler mandrels, liners, folding covers and grating covers

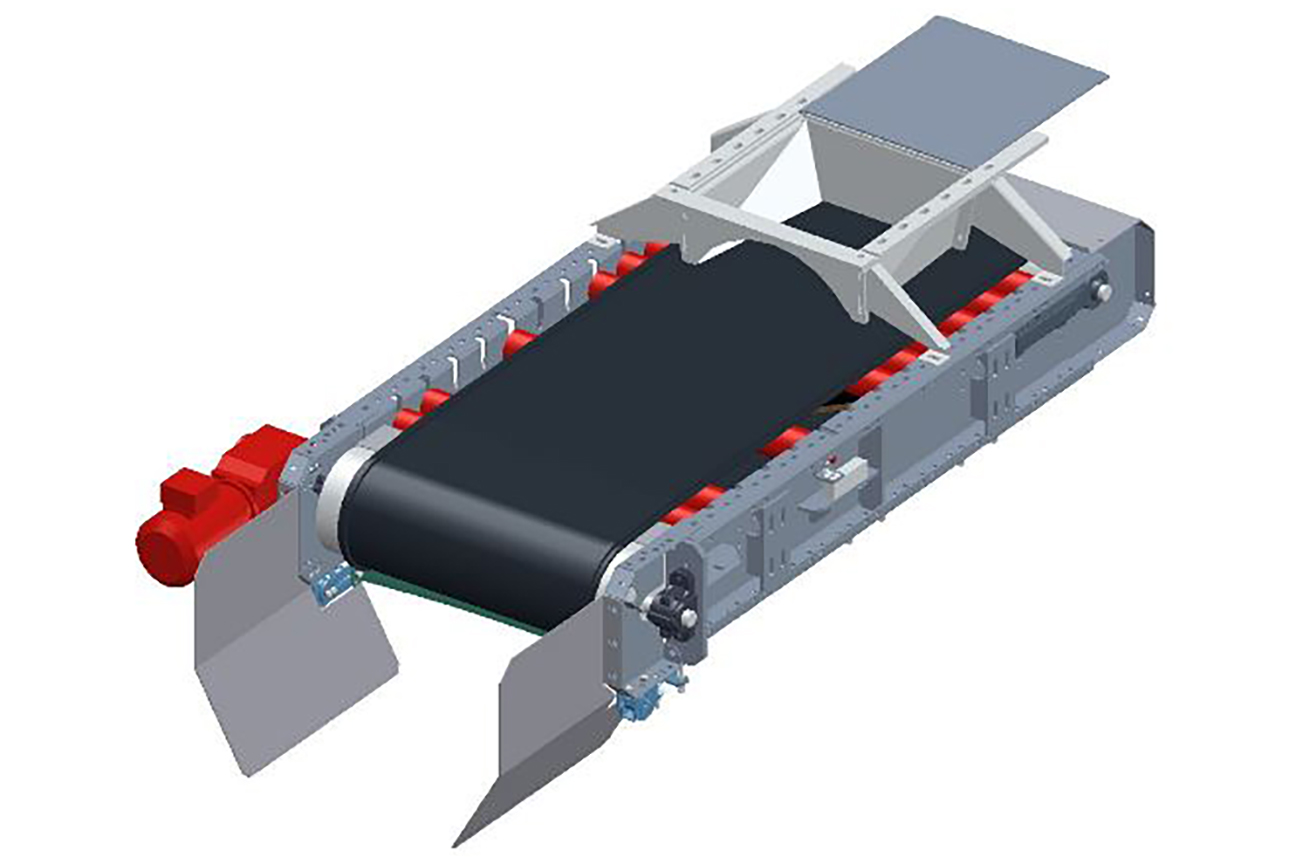

Dosing belt conveyor:

Compact system design

Scraper systems for your specific application

Sliding gates as shut-off spindle gate or push gate

Height-adjustable control gate

Various types of liner

Scales: Dosing belt scales, built-in belt scales, batch weighing (calibratable)

Talk to us to arrange a demo of the options available with our VHV dosing and weighing systems.

VHV sieve systems

Your advantages at a glance:

Open inlet aperture prevents clogging – even with balls of greensand

Pre-tensioned sprung sieve surfaces break up clods of sand

A wide range of sieve mesh sizes are offered to suit any individual requirements

Benefits for spare part inventories: all replacement sieves in a type series have the same outer dimensions – even for different sieve sizes.

Torsion-resistant sieve bodies

Height savings thanks to slim outlet apertures

Galvanised finishes offer optimum protection against corrosion

Low-maintenance design utilising easily accessible, identical sieve surfaces

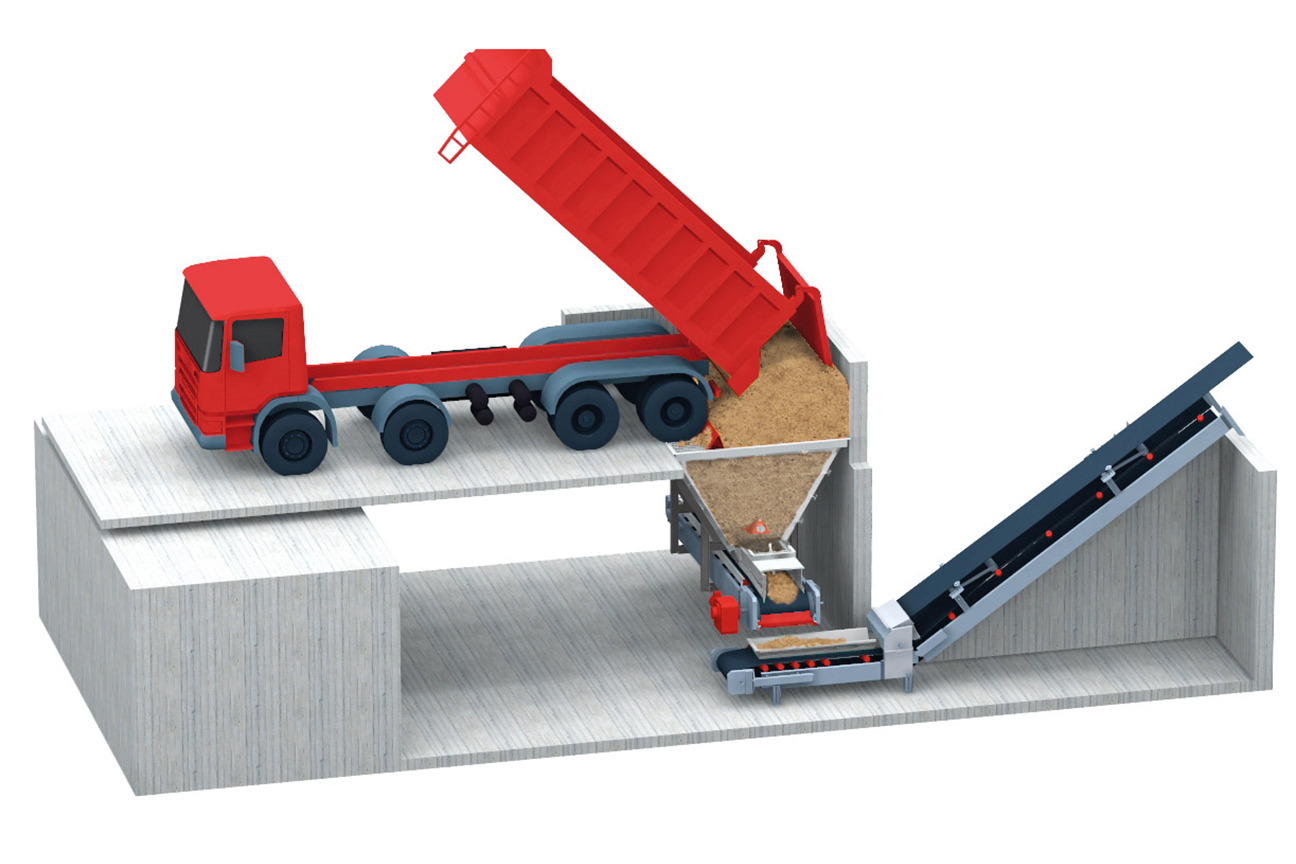

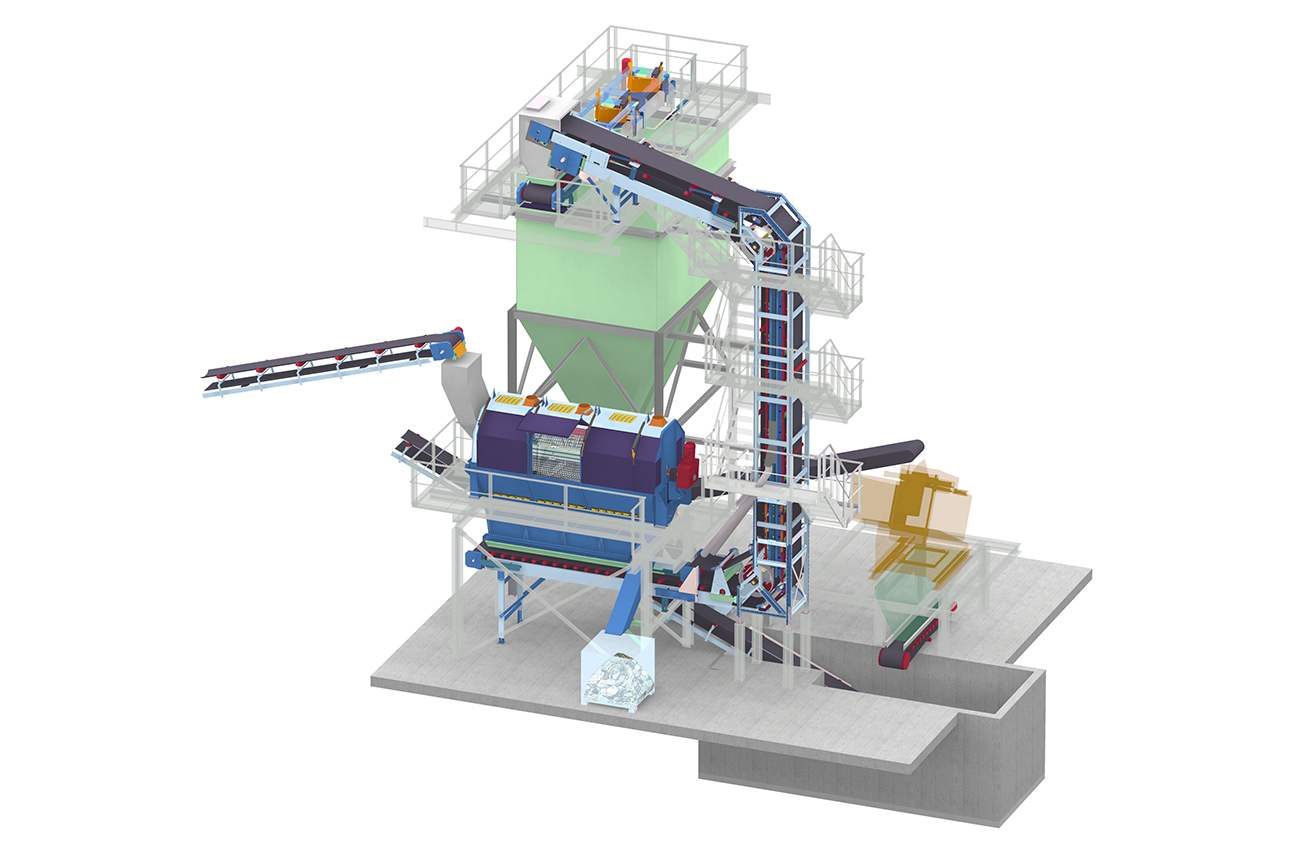

VHV belt conveyor discharge system also enables polygon sieve setups on the ground floor or basement

Controlled supply/exhaust air options for sand pre-cooling